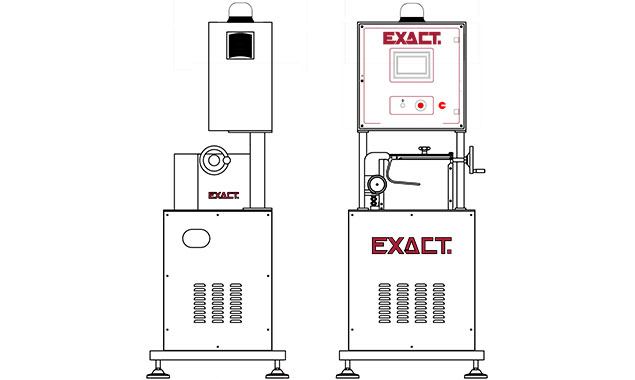

R6 JUMBO

SMALL AND EFFICIENT

Possesses all the features of its larger sister models, yet despite being the smallest of the Cold System Granulators, still provides synchronism with production line speeds and boasts both EXACT signature compression and cutting groups.

Its special construction features make the Jumbo model the perfect solution when working In Line with Raffia or High-Density Films, in production plants with low speeds.

TECHNICAL FEATURES

– Work speed up to 60 mt/min

– Hourly Production Rate up to 60 Kg/h

– Main Motor from 4 Kw

– Cutter Wheel diameter: 180 mm

– Standard cutter wheel from 18 blades; available in versions from 24 and 30 blades

– Pressure Bushes from 66 mm diameter

– Bushing sizes available PDP 1,5 / 2 / 2,5 mm

– Omron operator interactive color Touch Screen 7.5”

TREATED

MATERIAL

Suitable for the recovery of films containing mixtures of:

| PP | PE | HD | PVC |

The R6 JUMBO is also capable of recyling packaging straps and Raffia.

WEIGHT AND

DIMENSIONS

NET WEIGHT (kg): 340

WIDHT (mm): 750

DEPTH (mm): 650

HEIGHT (mm): 2000

ACCESORIES