A SYNTHESIS

OF THE OPPOSITE

After years of perfecting its Cold Technology Systems, EXACT completes its range of machinery by finally offering its Hot Granulator Systems. The common extrusion processes are reinterpreted and improved by our decades of experience in the field of thermoplastic film trim recovery, to guarantee the renowned EXACT precision even in thermal transformation processes.

|

|

TOP FEATURES

SHORT PAYBACK

Rapid return on investment due to its low cost and optimal material recovery potential.

CUSTOMIZABLE

All granulator machines can be customized to adapt to any working conditions.

COMPACT

All granulators have a small footprint and minimum operating space is required.

SILENT

Specially designed Tow system not requiring the use of noisy air trim extraction systems.

EASY CONTROL

Touch screen (PLC) and intuitive functions for greater ease of use.

LOW MELT TEMPERATURE°

Special screw design eliminates fusion peaks and excessive material stress.

APPLICATIONS

BUBBLE FILMS

Thanks to External Synchronism, EXACT granulators regulate the speed of recovery to work in perfect harmony with any extrusion plant.

CAST SYSTEM

EXACT granulators work perfectly even with flat headed extrusion lines

WASTE REELS

EXACT has all the technology available to recover Off-Line reels of any type of material.

WORKING

CONFIGURATION

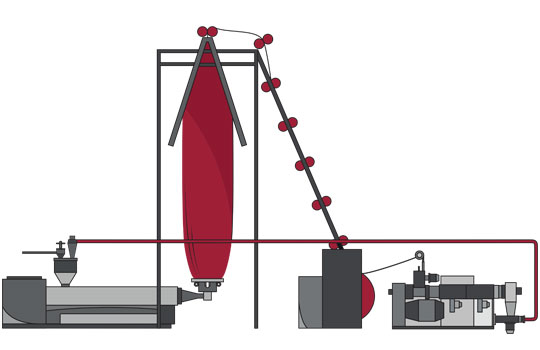

IN LINE RECOVERY

EXACT granulators are designed to operate in a continuous cycle, recovering edge trim directly from the film producing line. The granulator transforms the trim into granules that are stored and re-injected into the gravimetric dispenser by special lances.

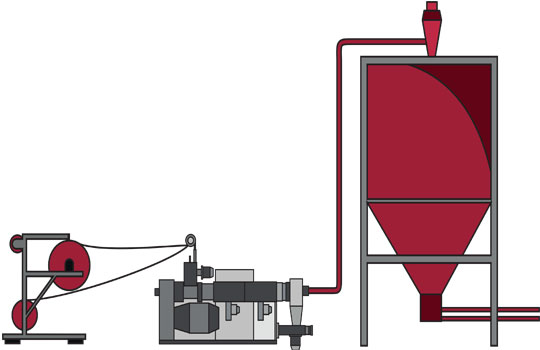

OFF-LINE RECOVERY

EXACT granulators have all the technology and strength needed for the recovery of waste reels of any width and/or diameter. Thanks to the Slitter cutting blades of EXACT’s customized Unwinding Stands (link) it is possible to recover film reels in sectors.