FORCED FEEDERS

PERFECT FOR RE-FEEDING THE EXACT CHIP OR LIGHT GRANULES

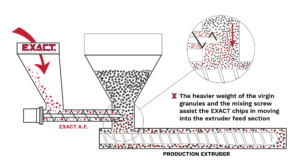

Our Forced Feeders are the perfect solution for the reintroduction (in a closed cycle) of a homogeneous mixture of regranulate and virgin resin, into the production extruder.

Even in cases where the regranulate has a lower weight than the virgin resin, re-feeding and mixing are ensured because of three factors:

– Positioning of the feeder under the gravimetric hopper: the heavier weight of the virgin granule pushes even the lightest regranulates in the extruder, by simple gravity.

– Continuous mixing of the granules inside the connector area to ensure homogeneity in the re-feeding.

– Larger feeding mouth dimensions to avoid any blockage or bridge formation.

TECHNICAL FEATURES

– Coclea Screw Diameters: 60mm / 80mm / 100mm

– Motors Available: 0,75Kw / 1,5Kw

– Capacity: from 10Kg/h up to 500Kg/h

– Stainless Steel safety grill inside the Hopper

– Inspection window on Hopper

AVAILABLE VERSIONS

Constant Speed: This type of feeder does not allow regulating and/or dosing of the regranulate. The constant speed feeder must always work coupled with an open mouth extruder.

Variable Speed: : Controlled by an Inverter, it works as a volumetric doser.

Being able to adjust the speed of the feeding screw, it is possible to dose the feeding of the regranulate, in variable percentages.

It is also possible to synchronize the speed of the feeder screw with that of the extruder screw, to keep the percentage of regranulate to be re-fed with the virgin granule always constant.

Low Hopper Feeder: smaller in size. Excellent solution in instances of space shortage. Also used to feed materials with high electrostatic charge.

As with all EXACT solutions, our Forced Feders can also be customized to guarantee maximum performance and functionality.

Based on the production system properties, the feeding auger, its engine power and the correct reduction ratio can be determined in order to properly manage the re-feeding flow rate.

The connector piece supplied with the Feder will also be constructed to adapt to the size and flow rate of the extruder feed screw, thereby allowing for a perfect connection of the feder above the extruder mouth.