THE ORIGINAL EXACT TRADEMARK

FOR EDGE TRIM RECOVERY

EXACT originated almost half a century ago, after designing and developing a new edge trim recovery system. The intuition was precise: through a calibrated extraction, compression and cutting process it was possible to regranulate edge trimmings of thermoplastic film without waste, and without alternating the film’s fundamental properties. The end result? A simple to use machine with an extensive utility potential.

With 45 years of continued improvements and success, EXACT graulators have been launched in over 8000 plants worldwide; daily proof of the extraordinary effectiveness of our original intuition.

HOW IT WORKS

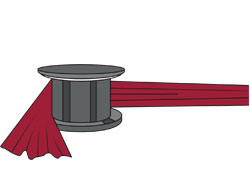

EXTRACTION

Thanks to an Infeed Device and Dancer, the edge trims arrives at a constant speed at the entrance of the Granulator. Conveyor guides then insure correct feeding of the machine.

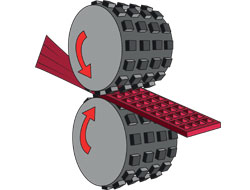

COMPRESSION

The trimmings enter the machine and are compressed by special Bushes with a diamond profile. The trimmings are transformed into a semi-rigid web.

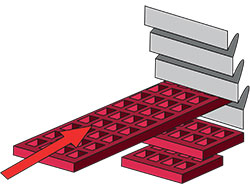

CUT

The Cutter Wheel divides the webbing into the characterisitic EXACT CHIP, a regranulate of high specific weight that has not undergone transformations due to secondary thermal processes.

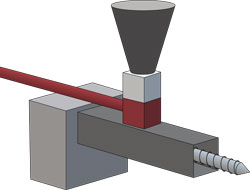

RECOVERY

The EXACT CHIP can be stored or put back directly into the extrusion process, eliminating the waste material

TOP FEATURES

NO MELTING

No further fusion. No alteration or material decay due to the addition of excessive heat

CUSTOMIZABLE

All Granulator machines can be customized to adapt to any working conditions.

ZERO FLUFF

Compact Granules with a high specific weight. No fluff and reduced risk of Hopper bridging in refeeding.

IMMEDIATE CLEANING

Simple and fast change over in material type or colour, with a large decrease in labor and waiting costs.

SHORT PAYBACK

Rapid return on investment due to its low cost and optimal material recovery potential

ENERGY SAVING

Low power consumption due to the absence of fusion and different motorizations starting from just 4Kw.

COMPACT

EXACT granulators have a small footprint and minimal operating space is required.

SILENT

Thanks to EXACT’s Infeed Device it is possible to avoid the use of noisy air trim extraction systems

APPLICATIONS

BUBBLE FILMS

Thanks to External Syncronism, EXACT granulators regulate the speed of recovery to work in perfect harmony with any system

CAST SYSTEM

EXACT granulators have all the strength necessary to recover even very thick films.

WASTE REELS

EXACT has available all the technology necessary to recover Off-Line reels of any type of material

WORKING

CONFIGURATION

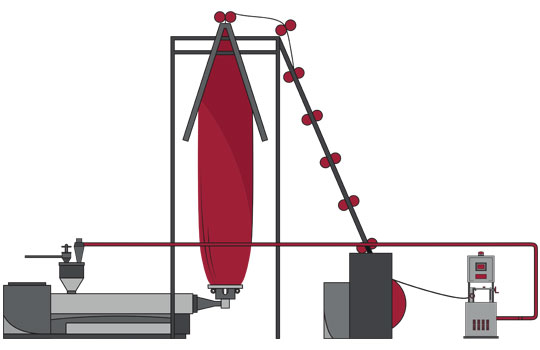

IN LINE RECOVERY

EXACT granulators are designed to operate in a continuous cycle, recovering edge trim directly from the film producing line, eliminating any risk of contamination due to the storage of the material. The granulator transforms the edge trim into granules which are immediately returned to the extruder Hopper and dosed together with the virgin granule. For best results, we recommend the use of EXACT A.F. Forced Feeders.

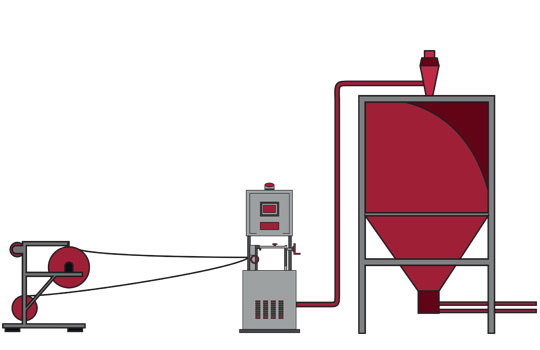

OFF LINE RECOVERY

Exact granulators possess all the technology and strength necessary for the recovery of waste reels of any width and/or diameter.

Thanks to Slitter cutting blades, and EXACT’s customized Unwinding Stands it is possible to recover film reels in sectors.