EVOLUTION 10

THE MOST VERSATILE GRANULATOR

Offers optimal management of medium thickness films and high speeds: characteristics that are found in most materials produced by film manufacturers.

Thanks to its technical specifications, and an extraordinary ability to work in-line, the Evolution 10 is the most versatile granulator in the Cold System family. The perfect choice for those who often change types of production and do not want recovery compromises.

TECHNICAL FEATURES

– Work speed up to 150-200 mt/min

– Hourly Production Rate up to 150 Kg/h

– Main Motor from 7,5 Kw

– Cutter Wheel diameter: 180 mm

– Standard cutter wheel from 18 blades; available in versions from 24 and 30 blades

– Pressure Bushes from 88 mm diameter

– Bushing sizes available PDP 1,5 / 2 / 2,5 / 3 mm

– Omron operator interactive color Touch Screen 7.5”

TREATED

MATERIALS

Suitable for the recovery of films containing mixtures of:

| PA | PC | PE | HDPE | LDPE | LLPDE | mLLDPE |

| PFA | PLA | PMMA | PP | PPS | PS | PTFE |

| PVOH | FEP | EVA | EVAL | EHPP | EVOH | CPP |

| PEEK | PES | PET | PU | PVC | BOPP | BOPET |

This unit can also successfully treat Mono or Multilayer films, Bi-oriented films, Bubble wrap, films containing mixtures of Calcium Carbonate and Titanium Dioxide, strapping for packaging, non-woven fabric, irrigation tubing, Raffia, Mater-Bi, BIO film and many other films with origins protected by trade secrets.

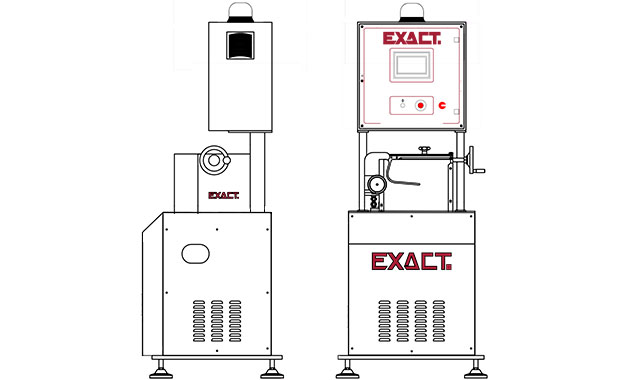

WEIGHT AND

DIMENSIONS

NET WIEGHT (kg): 550

WIDHT (mm): 830

DEPTH (mm): 840

HEIGHT (mm): 2160

ACCESORIES