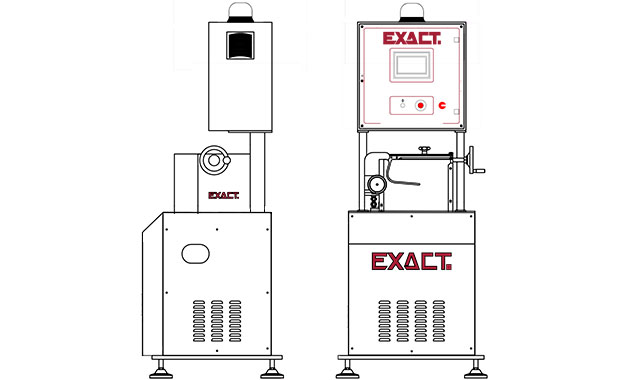

CYKLOP 20

PERFECT FOR LARGE PRODUCTION LOADS

Developed to meet the needs of highly technical markets, the Cyklop 20 granulator machine is particularly suitable for handling difficult materials such as non-woven fabrics, or very thick thermoplastic films with atypical production speeds.

This model has all the power needed to guarantee the best results even in high-speed film producing plants, and/or to recover off-line waste film reels ensuring a remarkable production rate in terms of kg/h.

TECHNICAL FEATURES

– WORK SPEED up to 200-250 mt/min

– HOURLY PRODUCTION RATE up to 200-300 Kg/h

– MAIN MOTOR from 15 Kw

– CUTTER WHEEL DIAMETER 200 mm

– STANDARD CUTTER WHEEL rom 24 blades; available in versions from 30 and 36 blades

– PRESSURE BUSHES from 102 mm diameter

– BUSHING sizes available PDP 1,5/2/2,5/3

– OMRON OPERATOR interactive color Touch Screen 7.5”

TREATED

MATERIALS

Suitable for the recovery of films containing mixtures of:

| PA | PC | PE | HDPE | LDPE | LLDPE | mLLDPE |

| PFA | PLA | PMMA | PP | PPS | PS | PTFE |

| PVOH | FEP | EVA | EVAL | EHPP | EVOH | CPP |

| PEEK | PES | PET | PU | PVC | BOPP | BOPET |

This model can also successfully treat Mono or Multilayer films, Bi-oriented films, Bubble wrap, films containing mixtures of Calcium Carbonate and Titanium Dioxide, strapping for packaging, non-woven fabric, irrigation tubing, Raffia, Mater-Bi, BIO film and many other films with origins protected by trade secrets.

WEIGHT AND

DIMENSIONS

NET WEIGHT (kg): 680

WIDTH (mm): 830

DEPTH (mm): 960

HEIGHT (mm): 2340

ACCESSORIES