E-120

MULTIFUNCTIONAL STRENGHT

The EXACT E-120 can generate In-Line yields up to 120kg/h.

Capable of operating at very high speeds and with multiple working configurations, the E-120 Extruder is a real problem solver. Due to

its independently adjustable Towing system and razor-sharp Shredder positioned above the feeding mouth, the E-120 can simultaneously process waste reels and plastic film trimmings coming from a production line.

If coupled with air trimming extraction systems, it can granulate trimmings at very high speeds (even over 400mt/min) such as edge trim from CAST plant systems and other cutting machines. The Shredder’s powerful blades enable the processing of extremely thick films with ease.

Use of the E-120 Extruder allows for increased productivity with limited difficulty and enables movement towards zero waste.

EXACT’s E-120 can be the answer for the most demanding challenges faced in todays film recycling industry.

TECHNICAL FEATURES

– HOURLY PRODUCTION RATE up to 120 Kg/h

– MAIN MOTOR 22 kW

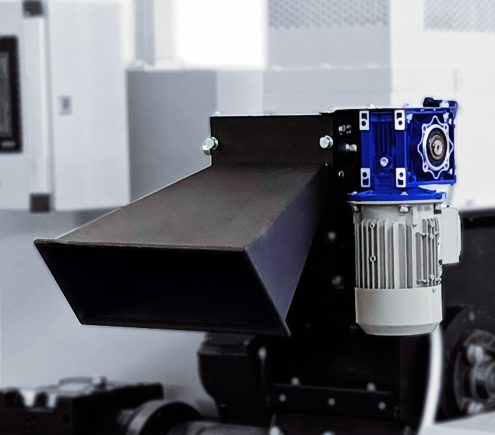

– TOWING double cemented rollers with compression springs enabling self-regulation of the roller pressure

– SCREW conical, nitride treated and of double diameter as per EXACT’s special design

– THERMOREGULATION 5 independent zones, 3 of which operate with double intervention (heating and cooling)

– TRANSDUCER 2 pressure transducers with temperature detection for melt fluidity control

– SCREEN CHANGER manual lever with double filter cartridge

– COOLING SYSTEM 3 fans for dissipation of heat generated by the barrel

– DIEFACE air cooled dieface and cutting unit with 2 or 4 blades

– OMRON OPERATOR interactive color Touch Screen 10”

TREATED

MATERIALS

Suitable for the recovery of films containing mixtures of:

| LDPE | LLDPE | mLDPE |

| HDPE | EVA | coPA |

| EVOH | PIB | PP |

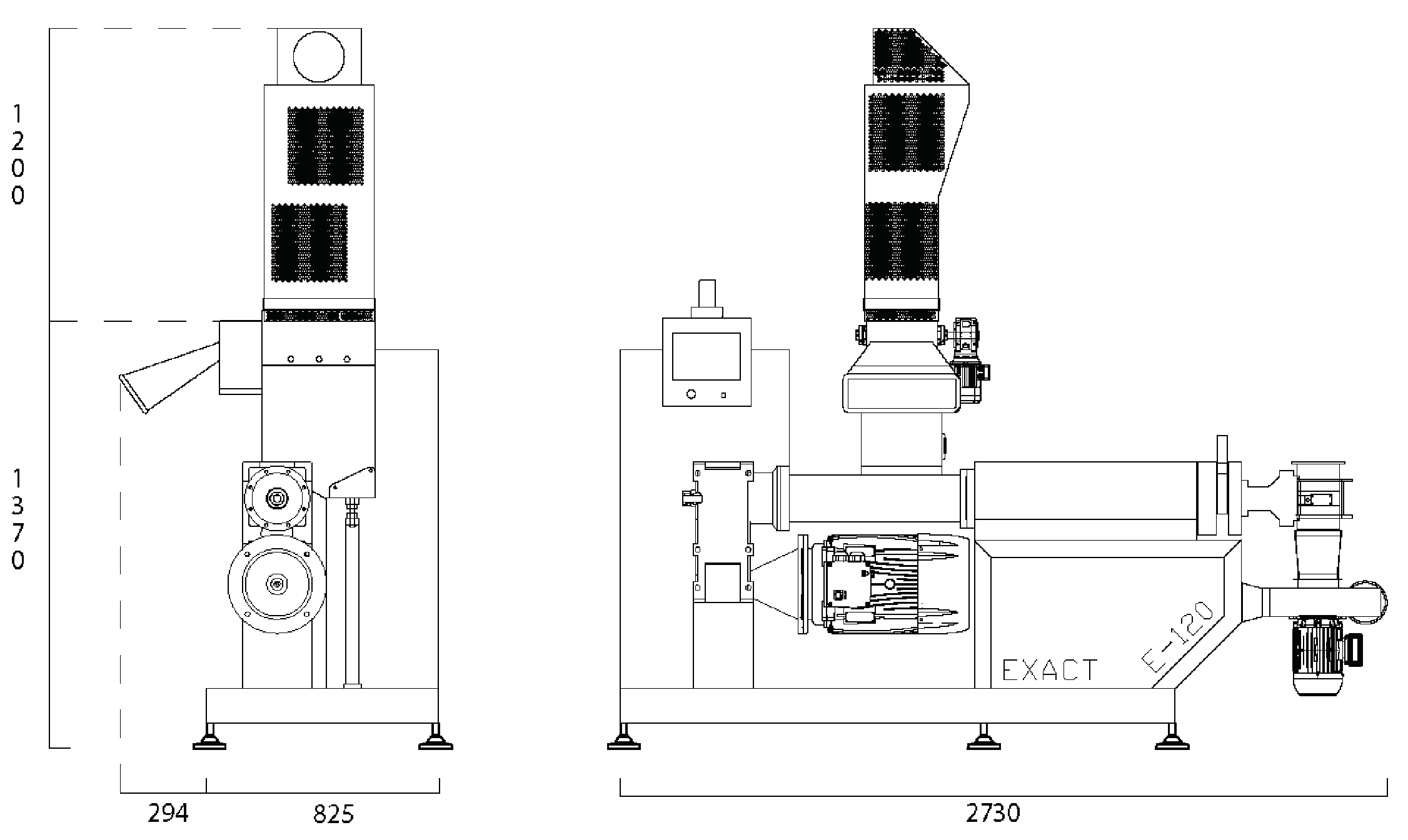

WEIGHT AND

DIMENSIONS

NET WEIGHT (kg): 1120

WIDTH (mm): 2730

DEPTH (mm): 294+825

HEIGHT (mm): 1370+1200

ACCESSORIES