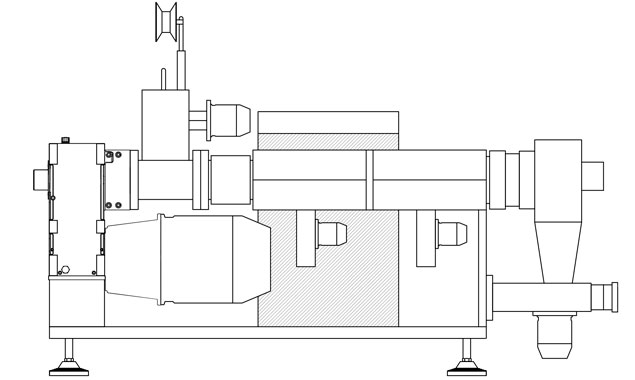

E-60

INTUITIVE EXTRUSION

Developed by EXACT and improved by continuous applications in the field, the E-60 is our Hot Pelletizer machine; ready to take on the challenges of intense daily use by Thermoplastic Film production plants.

This unit boasts a clean, visible layout, for quick and easy access to all of its components, and the best technology, derived from EXACT’s decades of experience in the Cold Recovery sector. The E-60 is equipped with our specially designed and renowned Tow system (link), avoiding the use of noisy air and/or other problematic systems; a screw designed and developed by EXACT for a gentle and controlled fusion of the edge trim to avoid stressing the films thermoplastic characteristics; and the potential to fully automate in-line recovery, eliminating any possibility of trim contamination.

Try EXACT’s Extruder E-60, and discover all the advantages for yourself.

TECHNICAL CHARACTERISTICS

– Working Speed up to 200 m/min

– Hourly Production Rate up to 75Kg/h

– Main Motor 15Kw

– Towing with high resistance crushing rollers to compact the trim and eliminate screw pulsations

– Sensor for signaling material deficiency which stops the screw in case of missing trim

– Nitrided screw with low L/D ratio complete with 3 thermoregulation zones: 2 with dual intervention (heating and cooling)

– Independent adjustment of, towing speed, screw RPM, and blade rotation speed

– Melt pressure transducer for material fluidity control

– Dieface and cutting unit air cooled with 2 or 4 blades

– Operator interactive colour Omron® touch screen – 7.5”

TREATED

MATERIALS

Suitable for the recovery of films containing mixtures of:

| LDPE | LLDPE | mLLDPE |

| HDPE | EVA | coPA |

| EVOH | PIB | PP |

WEIGHT AND

DIMENSIONS

NET WEIGHT (kg): 850

WIDTH (mm): 2200

DEPTH (mm): 750

HEIGHT (mm): 1500

ACCESSORIES